Pinch valves

Our pinch valves are an aluminium double-shell construction that serves as the casing of the sleeve: a flanged tube constructed in one piece of rubber PARA (PA / 40), EPDM, HYPALON or VITON (FKM-FPM). The tube, directly connected to the pinch mechanism and shaped so as to ensure an opening obliged also in the presence of vacuum, controls the flow of the process liquid* (from the full opening to the perfect seal of the product).

Our valves types are:

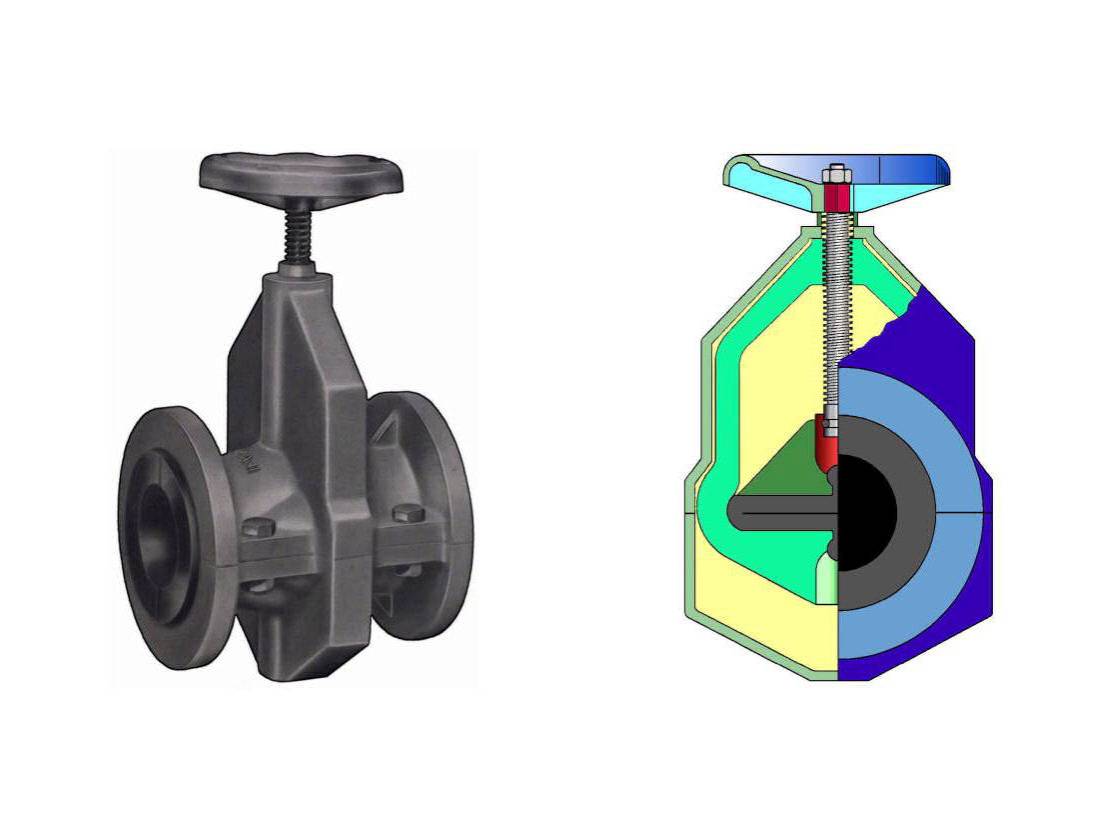

- Handwheel valves (type CO): if the control is carried out manually by the opening or the closing of the control screw;

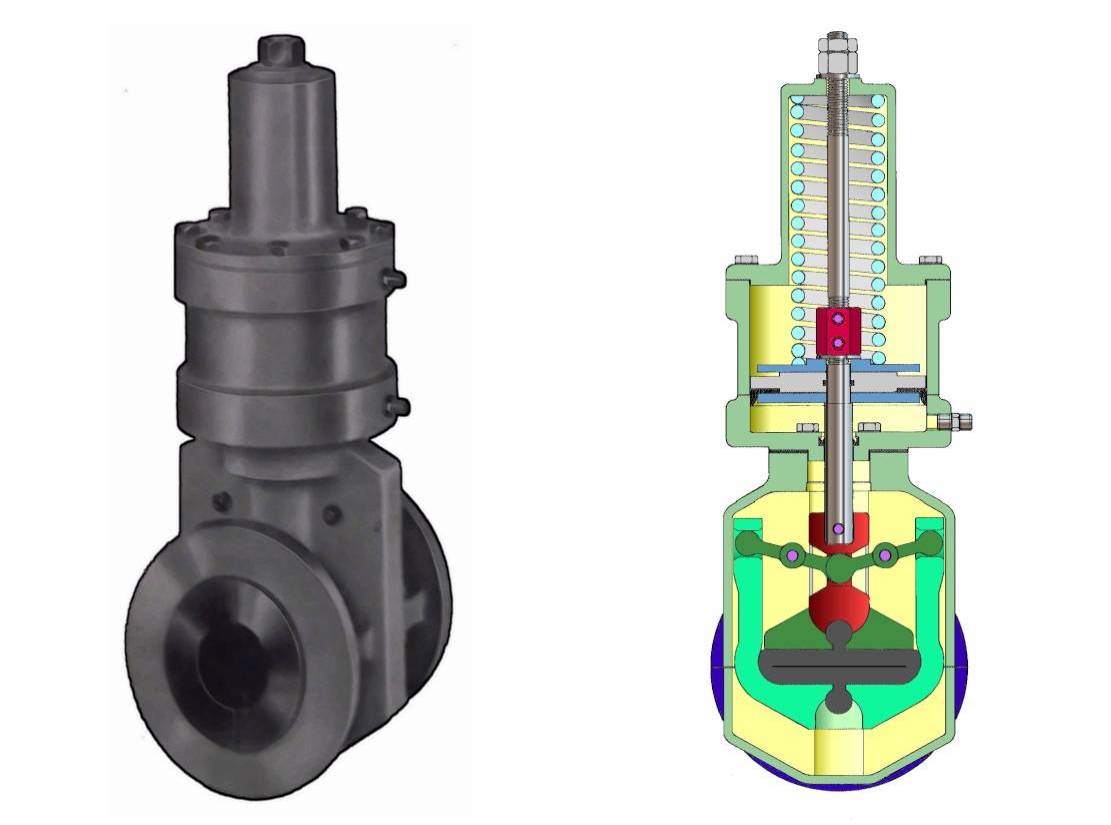

- Pneumatic valves (type COPM): if the control is carried out automatically by the opening or the closing of the control piston.

The flanged tube (or sleeve) is therefore the only element in contact with the process fluid and this involves:

- A minimum frictional resistance (pressure drop essentially zero, when the valve is fully open);

- The deformation of the sleeve during the closing process causes the breaking away of any incrustations inside the sleeve;

- Low costs of maintenance and low operating costs (the maintenance or the replacement of the sleeve is very simple and fast).

______________________

* The process medium is an acid or alkaline solution even highly corrosive (e.g.: hydrochloric acid, nitric acid, aqua regia, sulfuric acid at any given concentration, sea water, brine, bleach or solutions containing sodium hypochlorite at higher concentrations, solutions of silver nitrate or caustic soda solutions, sludge or lime slurry).